Why the factory is the first real market for humanoid robots

Humanoid robots may advance, but starting with home deployment faces safety concerns, unique challenges, and uncertain consumer demand. Factories make more sense.

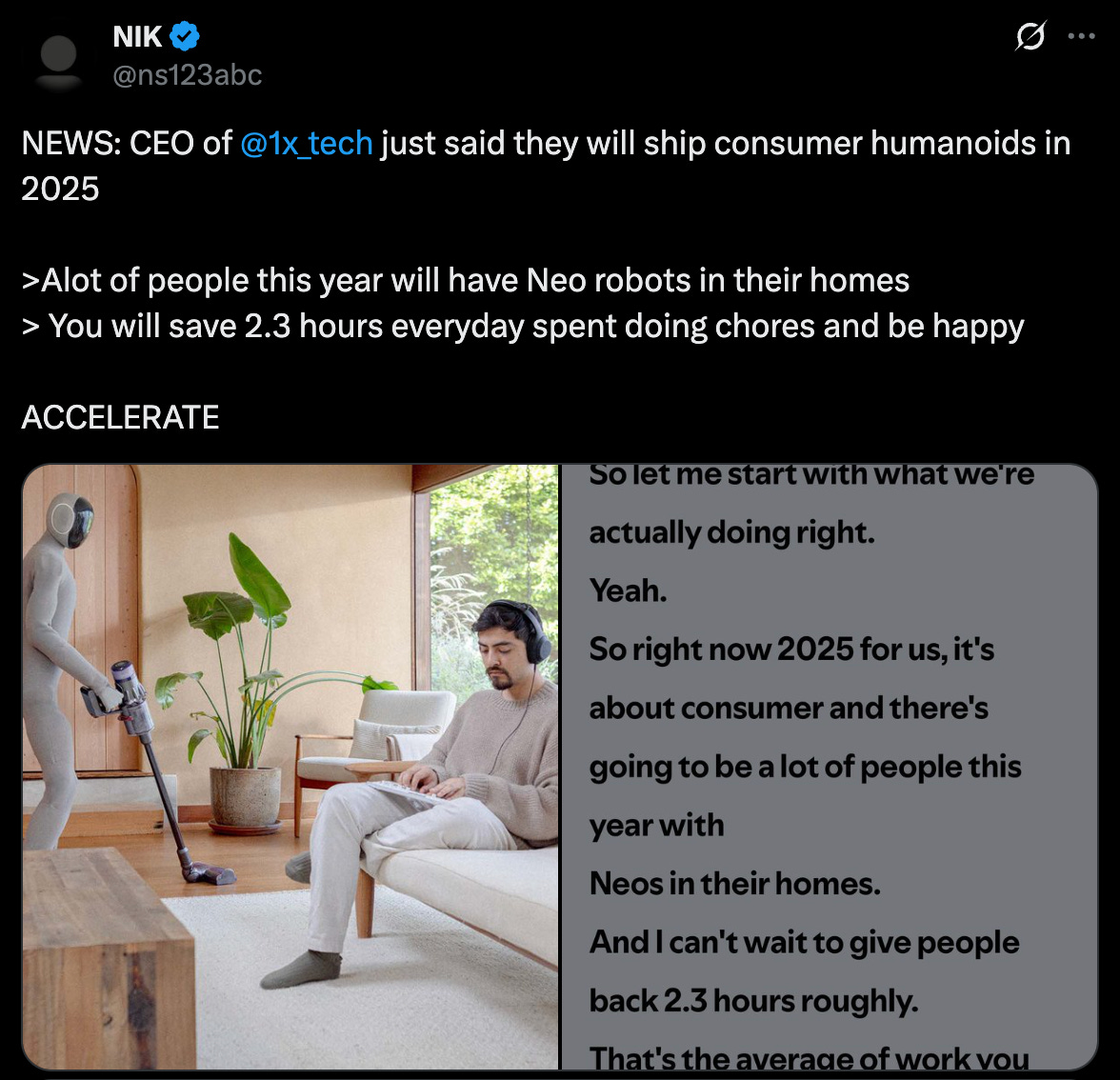

For decades, the ultimate vision for robotics has been a humanoid helper in every home, a real-life Rosie the Robot managing our daily chores. With recent advances in AI and hardware, this vision feels closer than ever. Companies like 1X have announced plans to ship their bipedal robots to consumers as early as 2025.

This rapid progress raises a critical question for the industry: Is the home, the most complex and personal of spaces, the right first market for scaling this technology? While the consumer market represents the ultimate prize, a closer look at the available applications suggests a more pragmatic path to mass adoption. The journey to the home robot will likely begin not at the front door, but on the factory floor.

The challenge of the home

The home environment presents a formidable set of obstacles for current AI and robotics. First is the issue of safety. A robot must operate flawlessly around unpredictable children, pets, and fragile personal belongings. Any failure could have significant consequences, damaging not just property but public trust in the technology.

Beyond safety lies the challenge of generalization. Every home is a unique, unstructured environment. AI models trained in a lab struggle to adapt to the sheer variability of real-world clutter, lighting conditions, layouts, and the changing arrangement of home objects, the classic “out-of-distribution” problem.

For a home robot to be genuinely useful, it must handle an immense number of tasks, from folding laundry to clearing a table. The economic value is also difficult to pin down. It remains unclear what price consumers will pay for a machine that can perform some chores well but fails at the countless edge cases of domestic life.

Amazon's Astro robot, a technologically impressive device, highlights this challenge. It has found a niche market among techa and gadget lovers but has yet to find a killer application that justifies mass-market adoption.

A step into the wild with package delivery

A more structured application is last-mile package delivery. Amazon is reportedly planning to test humanoid robots to carry packages from the delivery vehicle to a customer’s doorstep. This application has a clear business case, as it targets a specific, high-volume task with measurable economic returns.

A humanoid form factor offers a distinct advantage here by solving the "last 50 feet" problem. Unlike wheeled bots, a bipedal robot can climb stairs and navigate porches, reaching doors that would otherwise be inaccessible. However, this environment is still far from controlled. The robot must share public sidewalks with pedestrians, cyclists, and animals. It must interpret confusing obstacles like holiday decorations and adapt to changing weather conditions. Perhaps the largest barriers are not technical but regulatory and social. Gaining public acceptance and navigating the web of municipal regulations for sidewalk use are complex challenges that can slow deployment at scale.

The pragmatic power of the factory

This brings us to the factory and warehouse, which is emerging as the most viable first market for humanoid robots. Companies like Figure are already testing their 02 robot in BMW manufacturing facilities to handle automotive parts. Their newer models are testing more complex tasks, such as scanning and sorting packages of different sizes and forms.

The factory floor offers a controlled world that mitigates many of the problems found in homes and public spaces. The environment is predictable, with flat surfaces, consistent lighting, and structured workflows. This allows AI systems to perform reliably and makes safety protocols easier to implement and validate. The return on investment is direct and quantifiable through increased productivity, 24/7 operation, and filling labor shortages for repetitive or strenuous jobs.

A critical question for any enterprise is why they should invest in a general-purpose humanoid instead of a cheaper, specialized robotic arm. The answer is flexibility. A traditional robotic arm is highly efficient at a single, fixed task. When a production line changes, that specialized hardware may require significant re-engineering of the facility.

A humanoid robot, by contrast, is a flexible asset. It can be a "drop-in" solution for existing workstations that can be retrained with software updates. As AI researcher Andrej Karpathy explained in an interview with the No Priors podcast, in the long run, a general platform that can do many tasks will beat many disparate platforms that are designed for specific tasks. The robot can constantly be upgraded with new skills and applications, which can eventually be a very cost-efficient solution to many problems.

The flexibility of reliable humanoid robots can also unlock a new paradigm for manufacturing. Today, assembly lines are designed around the constraints of fixed automation. A fleet of general-purpose humanoids could enable dynamic production lines, reconfigured on the fly through software to meet fluctuating demand or introduce new products with minimal physical retooling. The factory itself becomes as agile as the robots working within it.

This versatility is the key. The path to scaling humanoid robotics relies on finding a market where the humanoid form is not just a novelty, but a core economic advantage. The factory is that market. It is a training ground where these machines can log millions of hours, refining their ability to manipulate objects and navigate spaces safely. The data gathered, the hardware improvements made, and the cost reductions achieved through manufacturing scale will provide the foundation for everything that comes next. The sophisticated, reliable robot that may one day enter our homes will get its start by first clocking in for a shift on the assembly line.